AGNI Burning Efficiency - High-efficiency burning with tertiary combustion

The disadvantages of softwoods, such as those from forest thinning, were that they burn at high temperatures and burn out quickly.

AGNI’s burning system maximizes burning efficiency with three stages of burning through the control of air flow with the robustness and higher airtightness provided by the AGNI Bell Cast thick-walled inner box construction.This enables the use of softwoods, which burn even when the air intake is restricted, maintaining high-efficiency burning and clean exhaust for many hours.

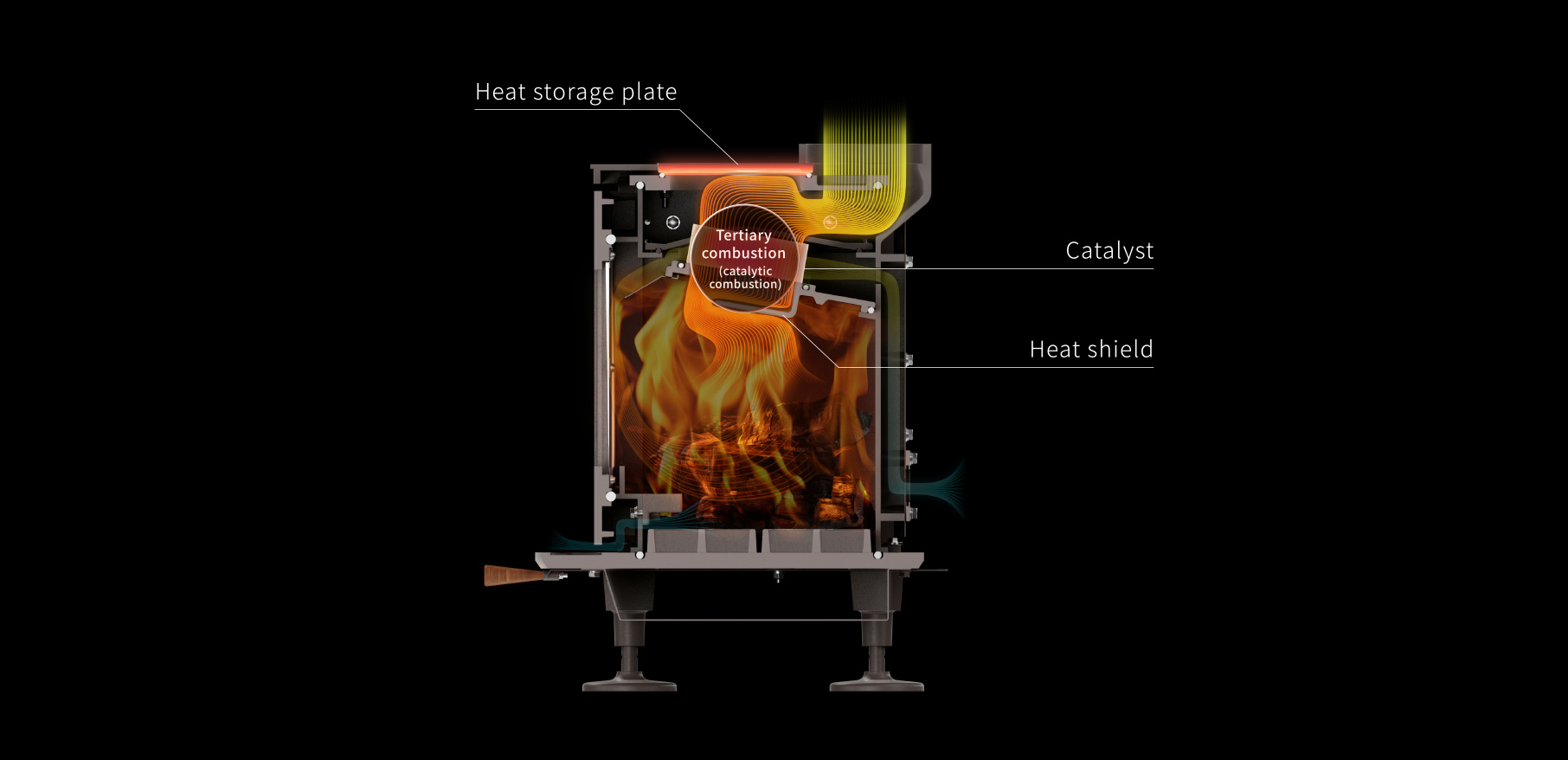

Mechanism of tertiary combustion

Primary combustion (when fire is first lit)

Fresh air is sent into the chamber from the air intake at the front of the stove to promote combustion.

Secondary combustion (clean burning)

Indoor air is brought into the chamber from the air intake at the rear of the stove. The air brought in is heated by the baffle plate at the top of the combustion chamber and injected with momentum toward the glass window, reaching the firewood while keeping the large window free from dirt and fogging.

Unburnt gases inside the combustion chamber combine with this hot air and are burned off with secondary combustion (clean burning).

Tertiary combustion (catalytic combustion)

To completely burn any unburnt gases remaining in the chamber, AGNI uses tertiary combustion (catalytic combustion), in which air that has been cleaned with the heat shield is passed through a catalyst. Because the catalyst works even when the air volume has been restricted, it also accommodates the use of softwoods, and burning to extreme levels results in clean exhaust. The heat storage plate, which also serves as a griddle directly above the catalyst, absorbs the combustion heat, thus maintaining the heat of the stove itself.

Patent obtained

AGNI’s burning system is a structure in which secondary air taken in from the rear is heated inside the baffle plate to conduct clean burning, and any unburned gases after combustion are broken down by passing them through a catalyst.Further, the heat storage plate absorbs the burnt gases, raising the burning efficiency of the stove.

AGNI’s maximum burning time (AGNI-C)

-

-

An AGNI wood stove (AGNI-C) can hold approximately 18 kg of hardwood and 12 kg of softwood. At high burning efficiency, it will burn 1.5-2 kg of firewood in an hour. With 18 kg of firewood, the fire will burn for around 9-12 hours.

*This data has been published based on the results of burning (measured in AGNI-C) conducted by our company.

Various factors other than the stove itself may affect burn results, such as the dryness and thickness of the firewood, chimney length, and drafts.